During 2018, we worked with representatives from the Altran Hořice development testing laboratory to prepare the implementation of a 31 m3 climate and solar walk-in chamber. We are not afraid of our customers' non-standard requirements, so we welcomed this challenge. We gradually specified all the needs and technical requirements for this chamber.

The needs of commercial testing laboratories may differ from those of manufacturing companies. In commercial testing labs, the emphasis is on maximum flexibility of the entire solution to cover the full range of requirements not only of automotive customers, but also, for example, customers from the aerospace, transportation, military technology sectors, and other industrial fields. Therefore, thorough project preparation was essential. Thanks to this, we successfully completed the entire implementation—from design, through delivery and setup—at the beginning of this year. The Altran Hořice development testing laboratory now offers an expanded portfolio of its services thanks to our solution.

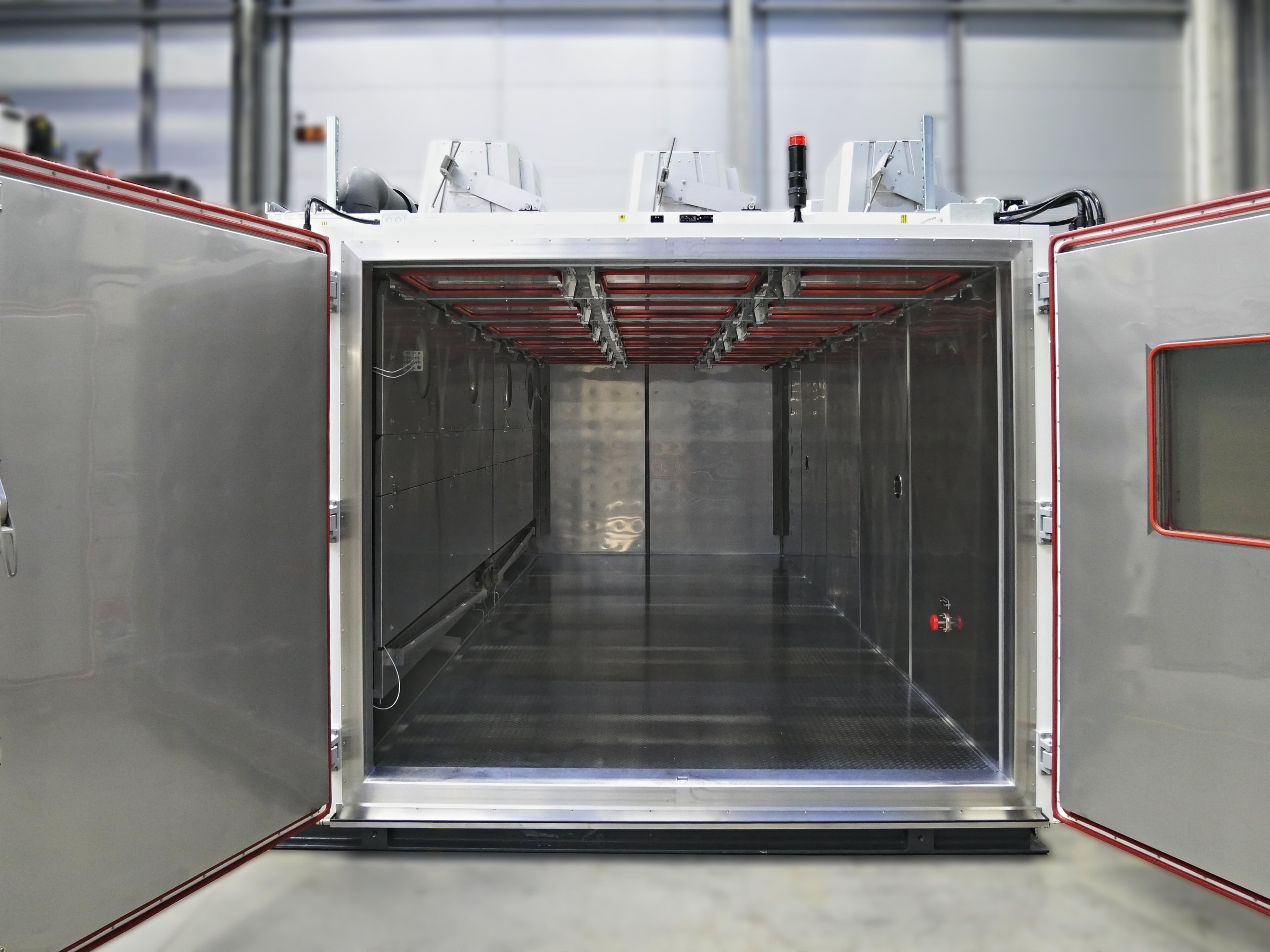

As we mentioned, the needs of commercial testing laboratories can be specific. Maximum flexibility of the equipment, minimized operating and ownership costs, minimal external dimensions relative to maximum internal dimensions, and long equipment lifespan are all important factors. That’s why we chose the climatic and solar Walk-In chamber model VK 31/35-120/So from VÖTSCH INDUSTRIETECHNIK. This is a walk-in chamber of approximately 31 m³, designed for testing larger parts and entire assemblies. The chamber can be used in three modes: as a climatic chamber, a solar chamber, or a combination of both modes.

The solar simulation function of this chamber is achieved using 18 blocks with 2.5 kW metal halide light sources. These blocks are installed in the ceiling of the chamber. Each block can be switched on and off independently. Such a flexible solution reduces operating costs in cases where the chamber is not fully loaded and testing is performed only in part of the chamber. The intensity of solar radiation can be adjusted, for example, according to standards such as DIN 75220, EN 60068-2-5, or BMW PR306.5. However, it is not necessary to limit yourself to only these standards.

Partial operation of the chamber was also considered in the design of the ventilation system. Usually, ventilation fans are placed at the rear of chambers. In this case, a side-mounted solution was designed, resulting in better air homogeneity inside the chamber. Thanks to this side ventilation solution, the overall external dimensions of the chamber, including accessories and the machine room, were also reduced.

We have met the customer’s requirements and are proud of the implemented non-standard solution. This project has once again advanced our capabilities as a supplier of testing and laboratory equipment.

David

Groh

Sales Manager

Ing. Gabriele

Benaglia

Sales Director