We helped expand the testing portfolio! In the first week of December 2019, the ceremonial opening of the renovated testing facility took place at the ZF Group Jablonec nad Nisou site.

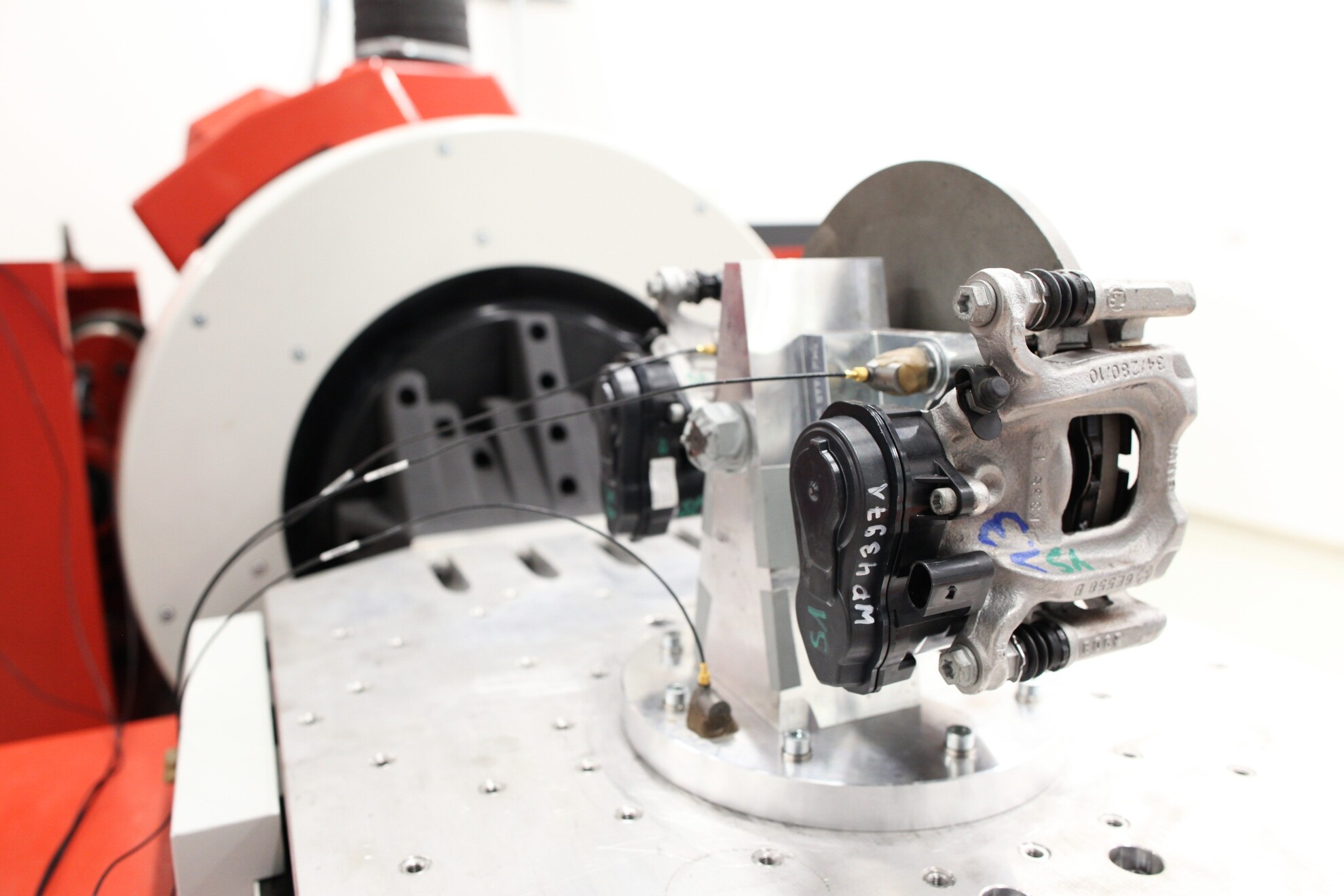

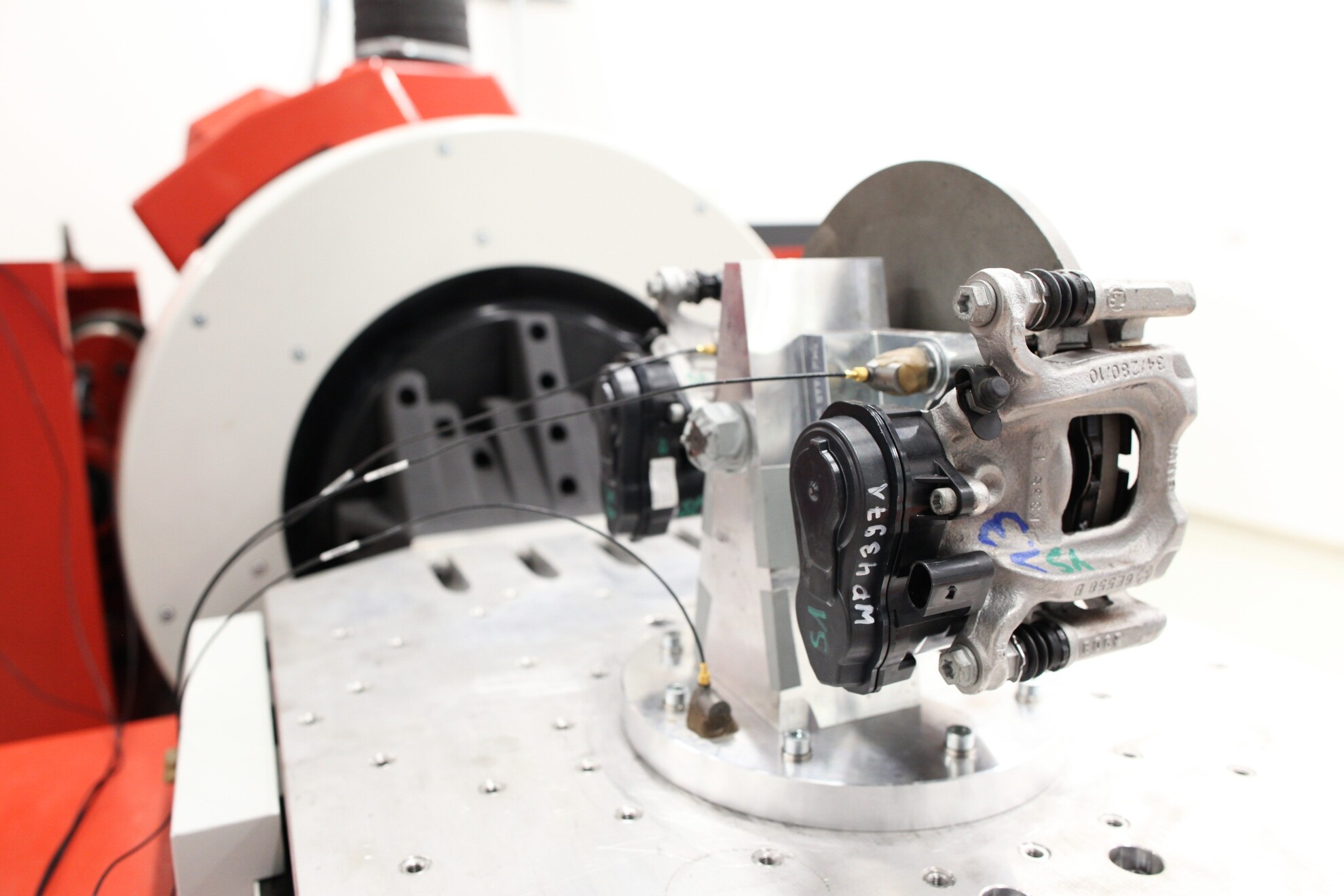

Our business partner, ZF Group, is one of the largest suppliers to the automotive industry in the world. ZF has been operating on the market for 100 years. At the Jablonec plant, with which we work closely in the field of testing, our partner develops and manufactures disc brakes, mechanical hand brakes, electric parking brakes, front disc brakes, and electric and mechanical actuators for passenger cars.

In 2015, ZF acquired TRW Automotive, a global manufacturer of passive and active safety components. The merger of ZF and TRW Automotive created a strong global company whose goal is to push the boundaries in the field of autonomous driving.

And what can we say? Safety comes first in the field of autonomous vehicles. That is why the components must be constantly tested and verified. This requires a large amount of various testing and trial equipment.

ZF Group is aware of this, and so in the first week of December 2019, the ceremonial opening of the renovated E4 building, newly named EPB TestFactory, took place at the ZF Group Jablonec nad Nisou site.

After about a year of rebuilding the entire building, employees were able to move new and older equipment into their brand new testing facility. This testing facility and laboratory is designed for complete testing of the EPB caliper.

Thanks to the new testing facility, there is no need to send test samples to external workplaces, other ZF branches, or commercial laboratories. This will allow our partner to achieve considerable savings in the coming years and increase its own efficiency in the development of its products.

In Jablonec, in addition to EPB durability tests, we have now expanded our testing portfolio to include environmental tests on vibration benches, tests in temperature shock chambers and also in spray chambers", said Ing. Petr Černý.

We are pleased to have been able to assist in the implementation of the new test facility. Our products used in the test facility include thermal shock chambers, temperature chambers, climate chambers, climate chambers for vibration equipment, and spray chambers, all from our partner, Weisstechnik. We have also successfully implemented VR9508 controllers from VibrationResearch for controlling vibration equipment.

In this way, we at Kaitrade indirectly contribute to the safety of cars. And we are happy about it!

Ondřej

Heřmanský

Sales Manager

Ing. Gabriele

Benaglia

Sales Director