Basic information

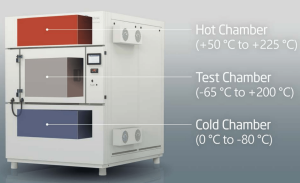

ShockEvent test chambers provide extremely rapid temperature changes in the range from -80°C to +220°C. This results in reproducible, certified and time-efficient tests that increase the reliability of the tested products. ShockEvent temperature shock chambers are manufactured with a test space (mobile basket) with a volume of 60, 120 and 300 liters. SchockEvent D chambers expand the aforementioned family of vertically mobile SchockEvent shock chambers. They are therefore an alternative to vertical test chambers. They are used for testing very sensitive components that could be affected by vibrations caused by the movement of the basket. The concept of the ShockEvent D chambers allows static temperature shock tests of vibration-sensitive samples and simple connection of measuring devices thanks to the concept of a static test chamber without vertical movement of the test space. The test temperature range of the ShockEvent D series is from -80°C to +225°C. The volume of the test space is 210 liters with dimensions of 700x500x600mm. It is possible to insert a sample weighing up to 100kg.